About Evergrande Transformer

About Us

Jiangsu Hengda Transformer Co., Ltd. is a professional manufacturer of transformers since year 2011. With registered capital 100 million RMB, occupied area 120,000 sqm, more than 356 staffs (nearly 100 engineering and technical members),we grow and expand rapidly in this industry and win the national high-tech award on 2019.

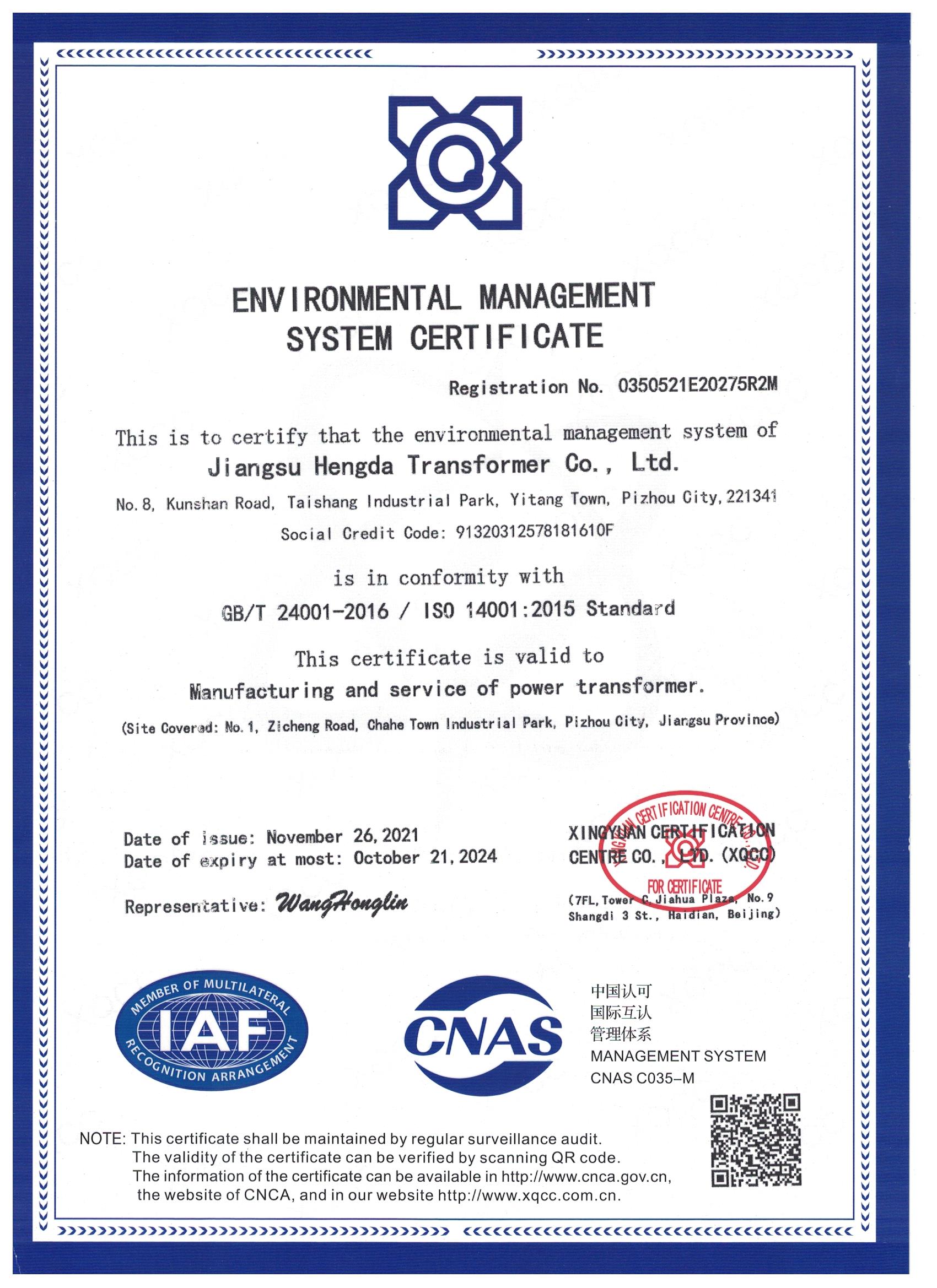

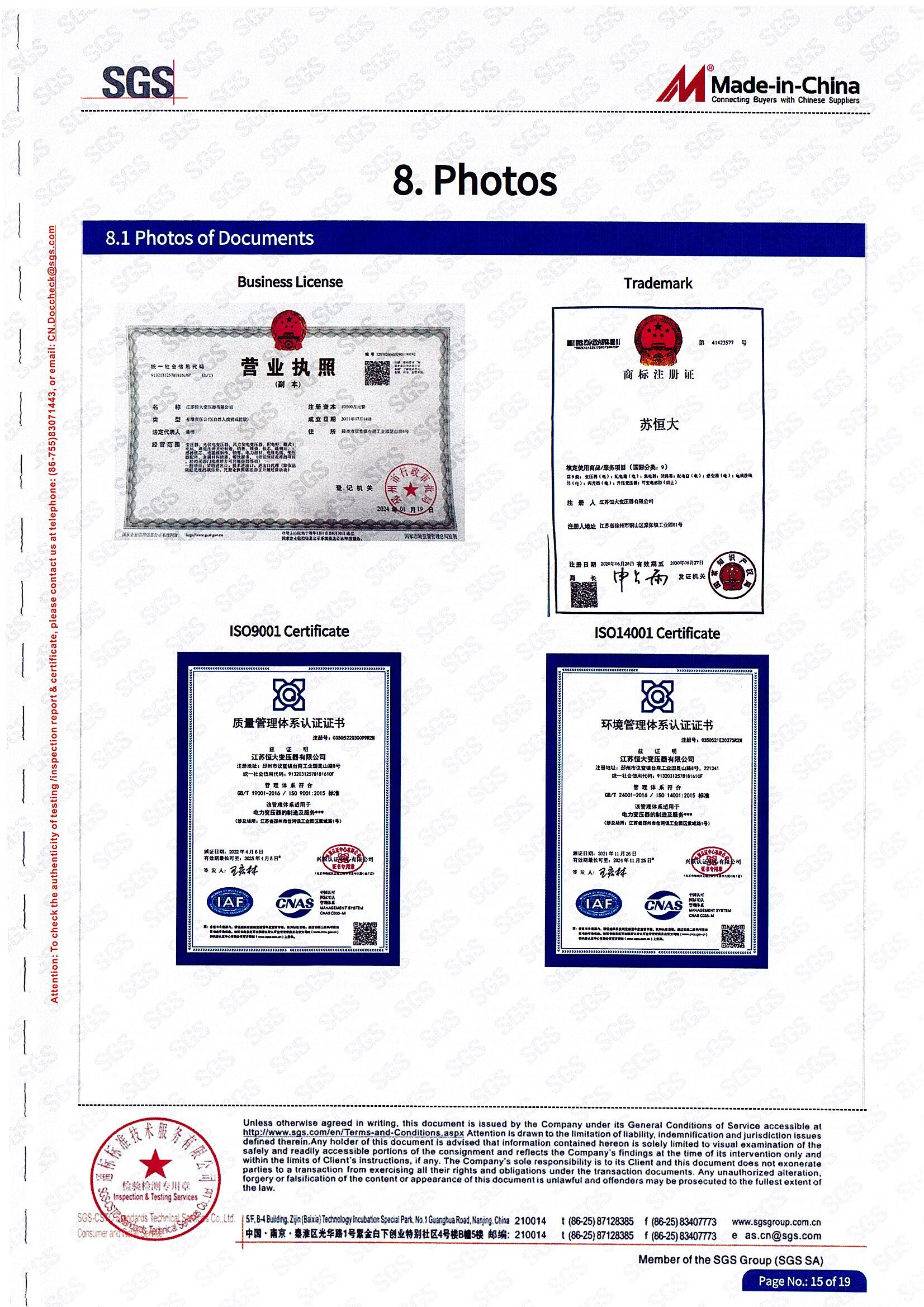

During these years, we have strong power with domestic market development, and are the qualified supplier of China National Power Grid & China Southern Power Grid (The top 2 Grids in China). Also we achieved ISO9001 Quality Certificate, ISO14001 Environment Certificate and ISO45001 Occupational health Certificate.

The company adheres to the values of “Win-win Concept, Innovation, Efficiency, Execution”, and takes the vision of becoming the most respected and trusted enterprise in the industry.

More about us

Please slide downwards

0

+COMPANY AREA/M²

0

+EMPLOYEES

0

+PATENTS

0

+PROJECTS COMPLETED

Jiangsu Hengda Transformer

The company adheres to the values of “Win-win Concept, Innovation, Efficiency, Execution”, and takes the vision of becoming the most respected and trusted enterprise in the industry. With excellent workmanship,guaranteed quality,competitive price,complete quality control system and worry-free custom service, Hengda will dedicated to provide you with first-class transformers and support your business grow bigger.

Factory

During these years, we have strong power with domestic market development, and are the qualified supplier of China National Power Grid & China Southern Power Grid (The top 2 Grids in China).

Future

With excellent workmanship,guaranteed quality,competitive price,complete quality control system and worry-free custom service, Hengda will dedicated to provide you with first-class transformers and support your business grow bigger.

Chinese high-quality transformer manufacturer

Throughout its production and operational activities, the company steadfastly maintains a quality policy that emphasizes complete involvement, a commitment to excellence, customer satisfaction, and ongoing enhancement.

Corporate Culture

Vision: To become a world-class transformer manufacturer

Mission: To create value for society, to create a better life for employees

- To createvalue for customers

- Let every employee feel the warmth of home

- Achieving world greatness

- Unity, innovation, efficiency, integrity, execution

- Gratitudeto society and parents

Core concept

Entrepreneurial concept: Perseverance and self-improvement

Business:Simple and Focused, Achieve Greatness

Sales:It is our honor to serve our customers

Salary: Pride in performance creation, shame in mediocrity

Performance: Only the first, no second

Employment: Loyalty first, ability second

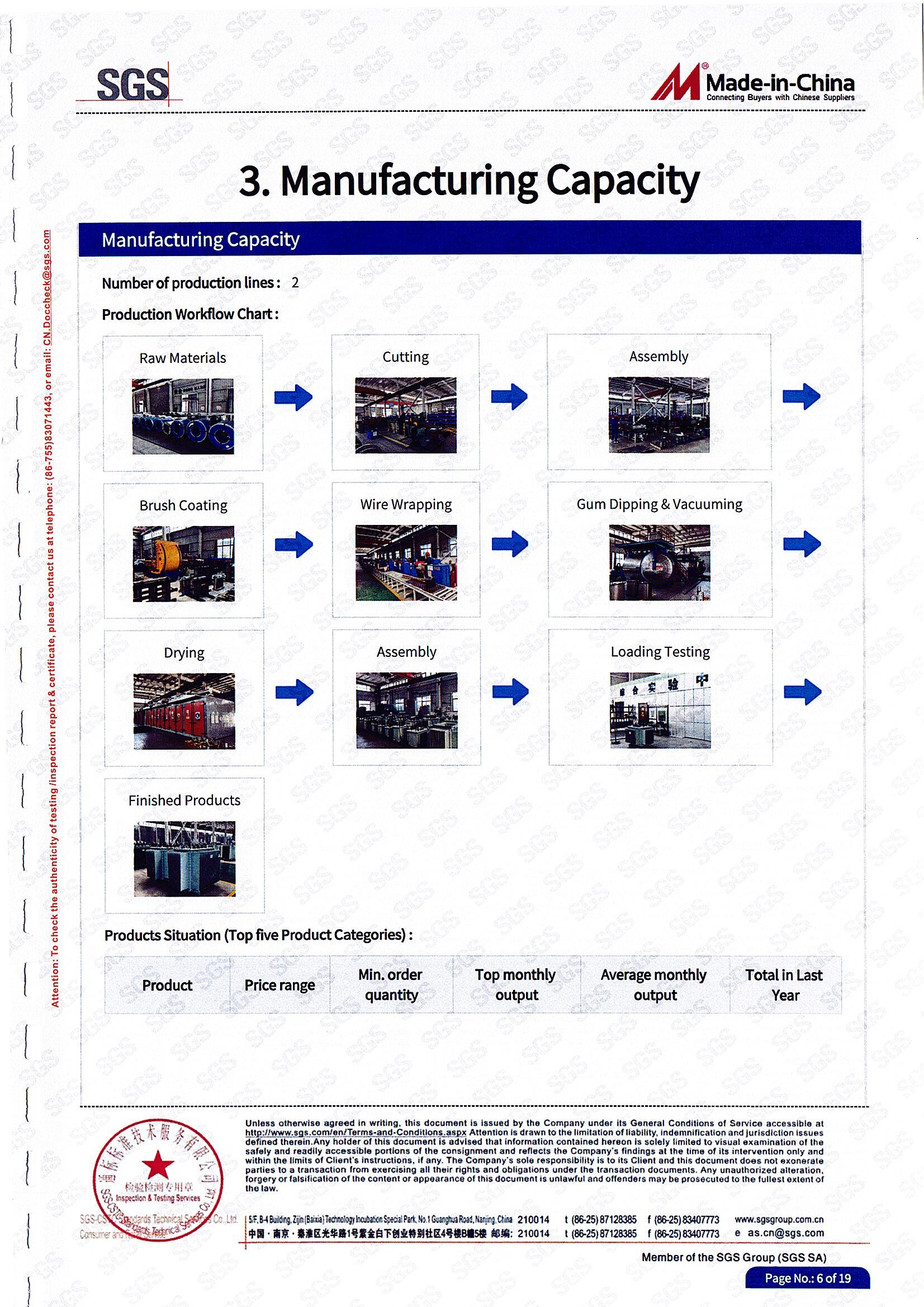

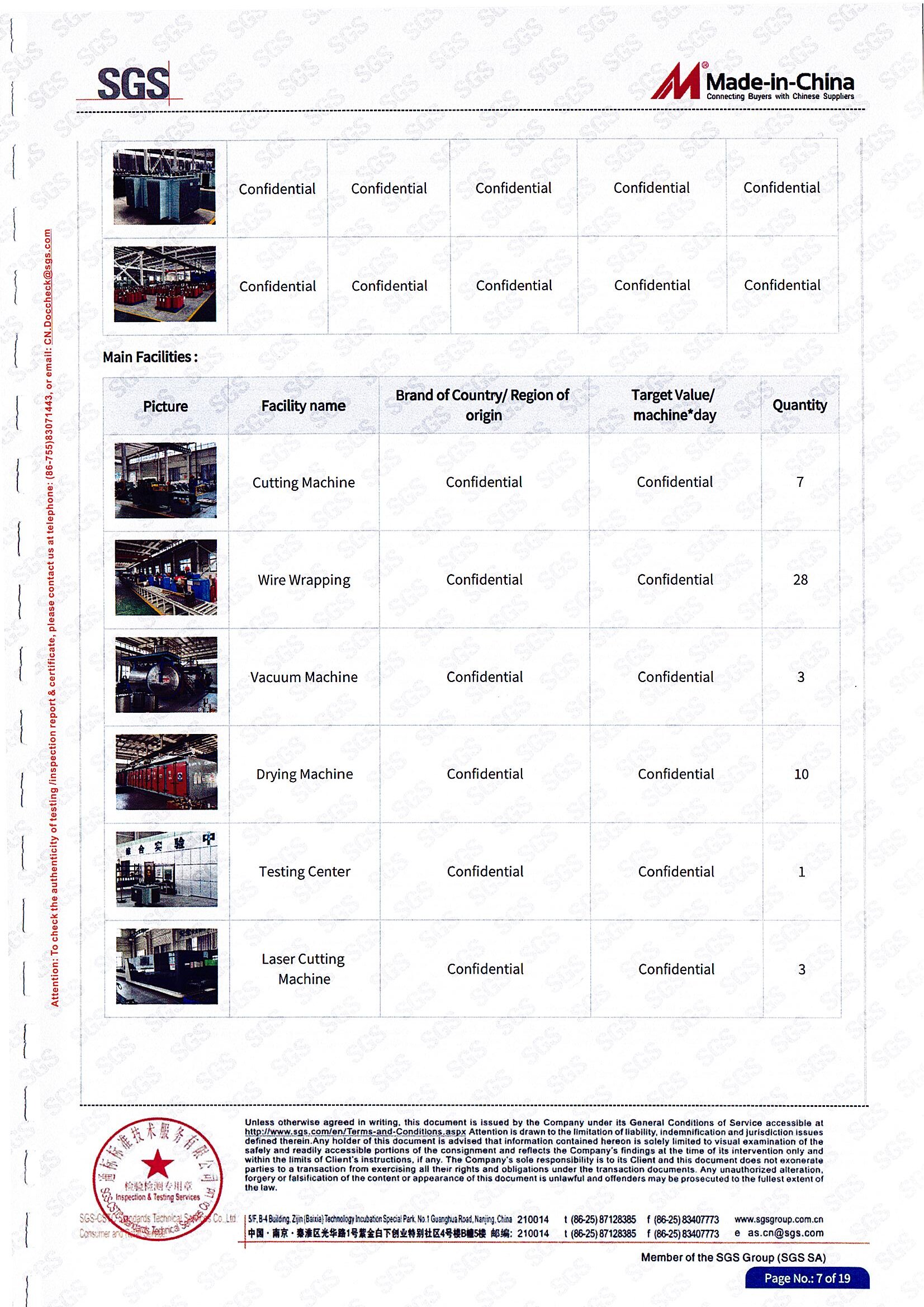

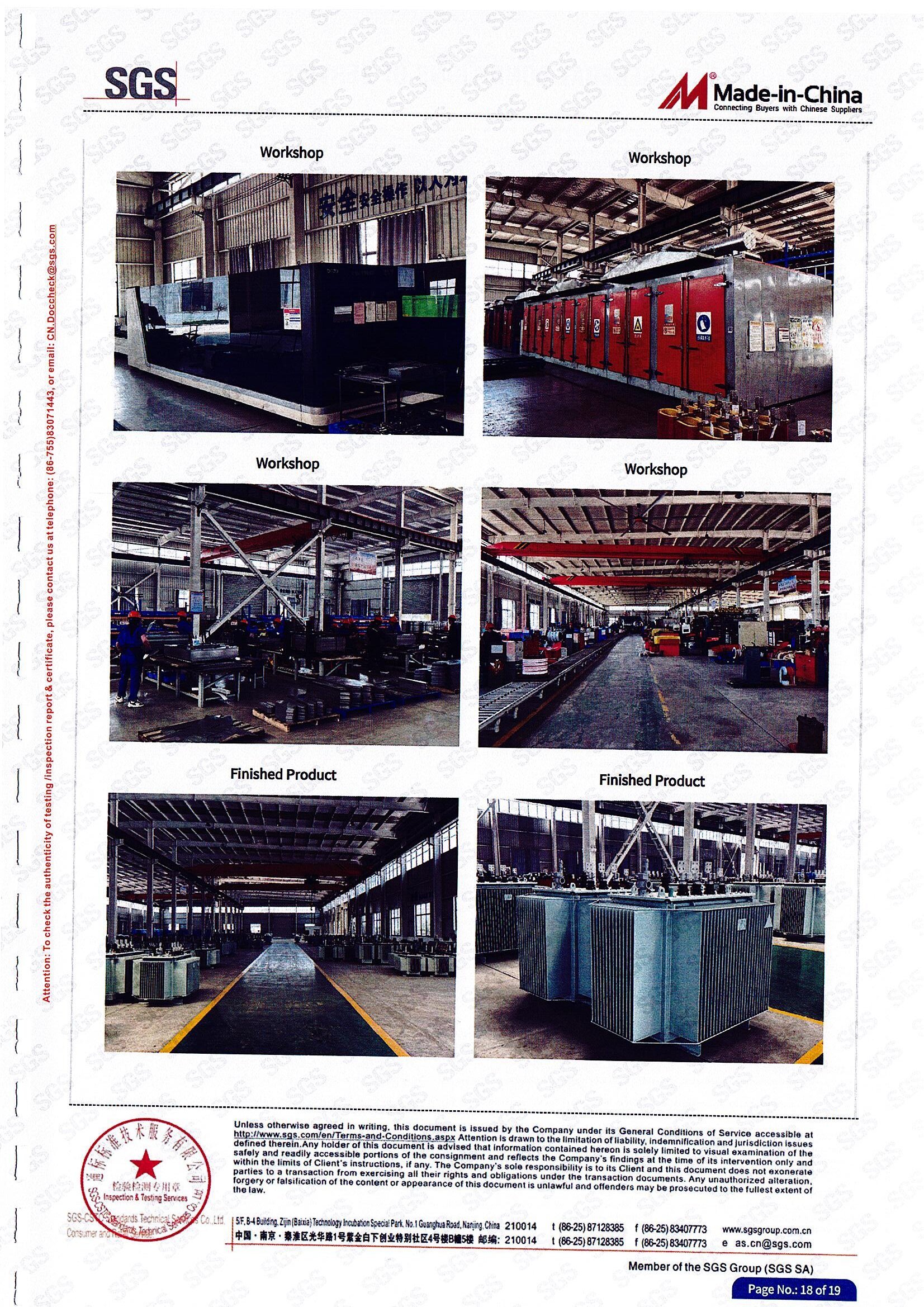

Advanced Production

- Automated production line

- Professional and experienced working team

- Strict selection and control of raw materials and accessories

- Complete inspection of each procedure

Capacity

- Oil Immersed Transformer 5,000pcs/Year

- Dry Type Transformer 5,000pcs/Year

Quality Control

- ISO9001 Quality Certificate

- ISO14001 Environment Certificate

- ISO45001 Occupational health Certificate

- IEC 60076 International Standards

Production Line

- New and in-roll raw silicon steel from famous brands Bao Steel, Wu Steel, Shou

- High tech lamination cutting machines

- Latest tech laser cutting machine

- Professional and well-experienced workers

Core

The transformer core is made of high-quality cold-rolled silicon steel sheets with high magnetic conductivity.

It has the characteristics of high efficiency, low loss, and low noise. It can save a lot of electricity consumption and operating costs.

Windings

High/low-voltage windings are selected high-quality oxygen-free copper wire, and multi-layer cylindrical structure.

The company has a strict quality inspection process, which includes incoming material inspection, process inspection, inspection, sampling, semi-finished product inspection, finished product inspection, inbound inspection, and outbound inspection. The quality is strictly controlled layer by layer.

Accessories

Pure copper conducting rod, Aero sealing ring suppliers, Hot-dip galvanized screw.

All components come from high-quality suppliers, controlling every detail from the source.

Casting

Fully automatic vacuum resin casting, with resin materials provided by Chinese listed companies.

Professional production equipment provides assurance for good product quality. And ensure that the high and low voltage coils after pouring are aesthetically pleasing and durable

Dryer

Full drying with 6-spaces drying equipment.

Adequate drying equipment ensures continuous and uninterrupted operation of the process, ensuring production capacity

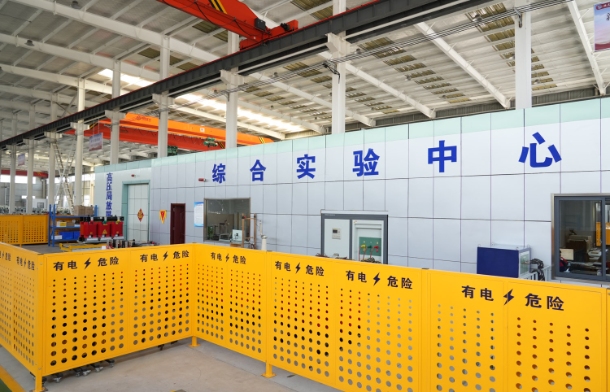

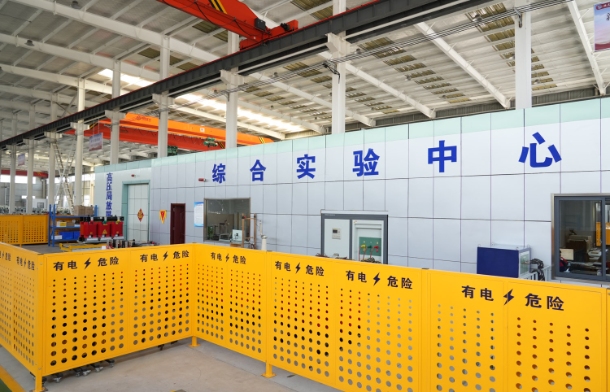

Testing

Routine Inspection and Type Inspection.

The company has a series of professional experimental equipment, including oil laboratory, finished product laboratory, partial discharge laboratory, temperature rise laboratory, etc., to ensure that each finished product undergoes a complete set of routine tests before leaving the factory, ensuring that the product tests are qualified and providing users with safe and stable high-quality products.

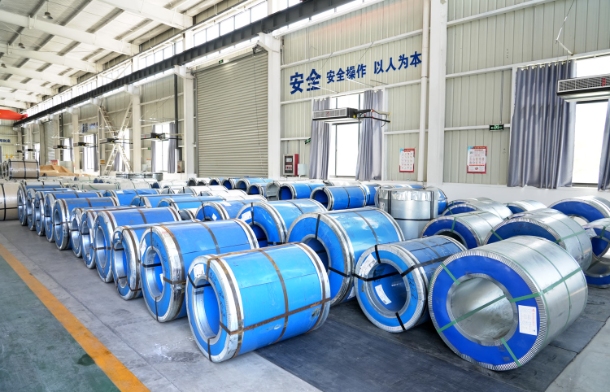

Warehouse

Tidy and clean, standardised large space.

Ensure sufficient stock of commonly used models, strong suppliers, source manufacturers for shipment, and quality assurance